IZINDABA YENKAMPANI

《 EMUVA UHLU

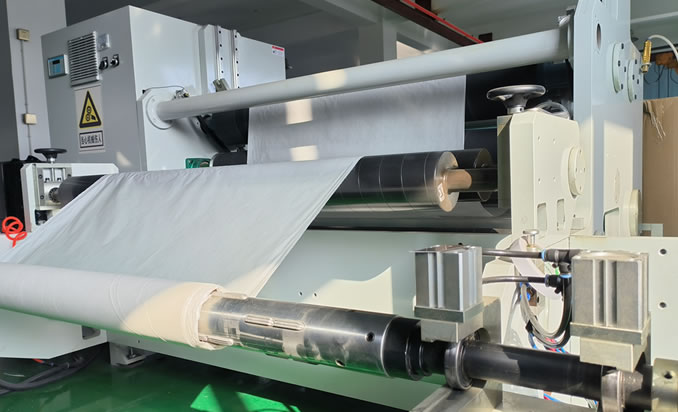

Ukugeleza kwenqubo yokukhiqiza ye-aramid

Iphepha le-Aramid ngokuvamile lilungiswa ngokuxuba imicu ye-aramid enezimvula nemicu emifushane ye-aramid yokwenza amashidi.

Ngokukhethekile, ngokwesibonelo, lezi zindlela ezilandelayo zingasetshenziswa: ngemva kokuxutshwa okomile kwemicu eshiwo ngenhla ye-aramid kanye nemicu emifushane ye-aramid, imicu ye-aramid enemvula kanye nemicu emifushane ye-aramid iyahlakazwa futhi ixutshwe endaweni ewuketshezi kusetshenziswa indlela yokugeleza komoya, bese emva kwalokho. akhishelwe emzimbeni osekelayo okwazi ukungena uketshezi (okufana nenetha noma ibhande) ukuze enze ishidi, futhi indlela yokukhipha uketshezi nokomisa iyathandwa. Lokhu okubizwa ngokuthi indlela yokukhiqiza emanzi, esebenzisa amanzi njengendlela ephakathi, iyakhethwa.

Inqubo yokukhiqiza iphepha le-aramid

Inqubo yokukhiqiza yokubumba yama-aramid fibers:

I-Polymerization: Esigabeni sokuqala, imicu ye-aramid iphothwa ibe izimpushana ze-polymer ezicinene, ezisanhlamvu. Le nto inezici ezishisayo namakhemikhali e-para aramid fibers. Kodwa-ke, ayinazo izinto eziqinisayo zentambo noma i-pulp. Le powder enhle ingasetshenziswa ukuthuthukisa izakhiwo zezingxenye zepulasitiki.

Ukuphotha: Esigabeni sesibili semicu ye-aramid, i-polymer incibilika ku-sulfuric acid ukuze kwakhe isixazululo sekristalu ewuketshezi. Kamuva, isixazululo saphothwa saba imicu emihle, ngayinye inobubanzi obuyi-12 μ M. Isakhiwo sikasilika singu-100% we-subcrystalline, namaketanga e-molecular ahambisana ne-axis ye-fiber. Lokhu kusatshalaliswa kokuthambekela okuphezulu kunikeza i-Twaron filament izici ezahlukahlukene ezinhle kakhulu.

Ifayibha emfushane: Ifayibha yokwenziwa emfishane noma i-fiber cut cut, ecutshungulwa ngokushwabana intambo bese iphathwa nge-ejenti yokuqedela. Ngemva kokumisa, sika imicu ibe ngobude obuqondiwe bese uyipakisha.

Ukuphotha ku-pulp: Ukuze kukhiqizwe i-pulp, imicu ye-aramid iqale isike intambo bese iyimisa emanzini ukuze ilashwe i-fibrosis. Bese ihlanganiswa ngokuqondile futhi ithengiswe njenge-pulp emanzi, noma iphelelwe amanzi futhi yomiswe njenge-pulp eyomile ukuze ithengiswe.