Iindaba zenkampani

《 Uluhlu lwangasemva

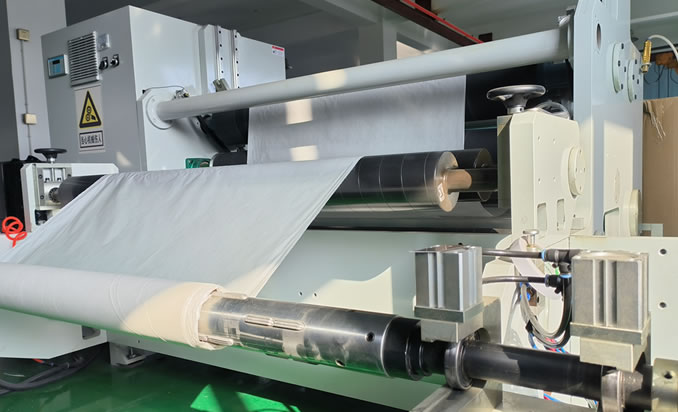

Inkqubo yokuvelisa i-aramid

Iphepha le-Aramid lilungiswa ngokubanzi ngokuxuba imicu ye-aramid ye-precipitated kunye nemicu emifutshane ye-aramid ye-sheeting.

Ngokukodwa, umzekelo, ezi ndlela zilandelayo zingasetyenziswa: emva kokuxutywa okomileyo kweefayibha ezikhankanywe ngasentla ze-aramid kunye neefiber ezimfutshane ze-aramid, iifibers ze-aramid ze-aramid kunye nemicu emifutshane ye-aramid ziyahlakazwa kwaye zixutywe kwindawo yolwelo kusetyenziswa indlela yokuhamba komoya, emva koko. ikhutshiwe kumzimba wenkxaso we-liquid permeable (njenge-mesh okanye ibhanti) ukwenza ishidi, kwaye indlela yokususa ulwelo kunye nokomisa iyakhethwa. Okubizwa ngokuba yindlela yokuvelisa emanzi, esebenzisa amanzi njengento ephakathi, ikhethwayo.

Inkqubo yokwenziwa kwephepha le-aramid

Inkqubo yokuvelisa i-aramid fibers:

I-Polymerization: Kwinqanaba lokuqala, iintsinga ze-aramid zijijwa zibe ngumgubo oshinyeneyo, ocolekileyo. Esi sixhobo sineempawu eziphambili ze-thermal kunye neekhemikhali ze-para aramid fibers. Nangona kunjalo, ayinazo iimpawu zokuqinisa umsonto okanye i-pulp. Lo mgubo ocolekileyo ungasetyenziselwa ukuphucula iipropathi zamacandelo eplastiki.

Ukujikeleza: Kwinqanaba lesibini lemicu ye-aramid, i-polymer inyibilika kwi-asidi ye-sulfuric ukwenza isisombululo se-crystal engamanzi. Emva koko, isisombululo saphonswa kwiifilaments ezintle, nganye inobubanzi be-12 μ M. Ukwakhiwa kwesilika yi-100% ye-subcrystalline, kunye namatyathanga e-molecular ahambelana ne-fiber axis. Olu nikezelo lotyekelo oluphezulu lunika iTwaron filament iimpawu ezahlukeneyo ezibalaseleyo.

Ifayibha emfutshane: Ifiber emfutshane eyenziweyo eyenziweyo okanye i-fiber cut short, ecutshungulwa ngokushwabana umsonto emva koko iphathwe nge-agent yokugqiba. Emva kokumisa, sika iintsinga zibe ngobude obujoliswe kuzo kwaye emva koko uzipakishe.

Ukujikela kwipulp: Ukuvelisa ipulp, iifiber zearamid ziqale zisike umsonto ze ziwuxhome emanzini ukuze zinyangelwe i-fibrosis. Emva koko ipakishwe ngokuthe ngqo kwaye ithengiswe njengepulp emanzi, okanye iphelelwe ngamanzi kwaye yomiswe njengepulp eyomileyo ukuze ithengiswe.