COMPANY NEWS

《 BACK LIST

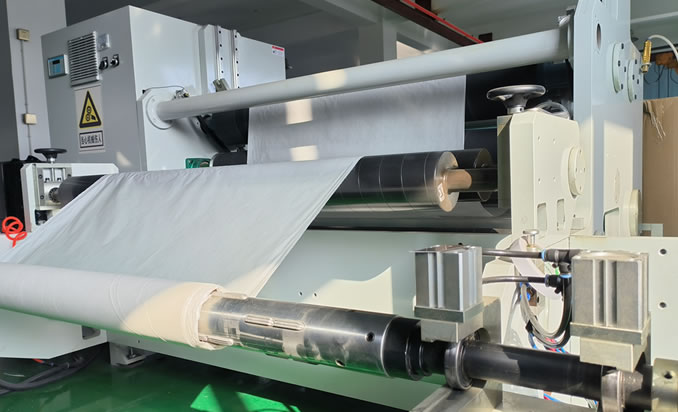

Production process flow of aramid

Aramid paper is generally prepared by mixing the aramid precipitated fibers and aramid short fibers for sheeting.

Specifically, for example, the following methods can be applied: after dry mixing of the aforementioned aramid precipitated fibers and aramid short fibers, the aramid precipitated fibers and aramid short fibers are dispersed and mixed in a liquid medium using an air flow method, and then discharged onto a liquid permeable support body (such as a mesh or belt) to make a sheet, and the method of removing the liquid and drying is preferred. The so-called wet manufacturing method, which uses water as the medium, is preferred.

The manufacturing process of aramid paper

The molding production process of aramid fibers:

Polymerization: In the first stage, aramid fibers are spun into dense, fine-grained polymer powders. This material has the main thermal and chemical properties of para aramid fibers. However, it does not possess the strengthening properties of yarn or pulp. This fine powder can be used to enhance the properties of plastic components.

Spinning: In the second stage of aramid fibers, the polymer is dissolved in sulfuric acid to form a liquid crystal solution. Subsequently, the solution was spun into fine filaments, each with a diameter of 12 μ M. The structure of the silk is 100% subcrystalline, with molecular chains parallel to the fiber axis. This high tendency distribution gives Twaron filament various excellent characteristics.

Short fiber: Artificial short fiber or short cut fiber, which is processed by wrinkling the yarn and then treated with a finishing agent. After drying, cut the fibers into target lengths and then package them.

Spinning into pulp: To produce pulp, aramid fibers first cut the yarn and then suspend it in water for fibrosis treatment. Then it is directly packaged and sold as wet pulp, or dehydrated and dried as dry pulp for sale.